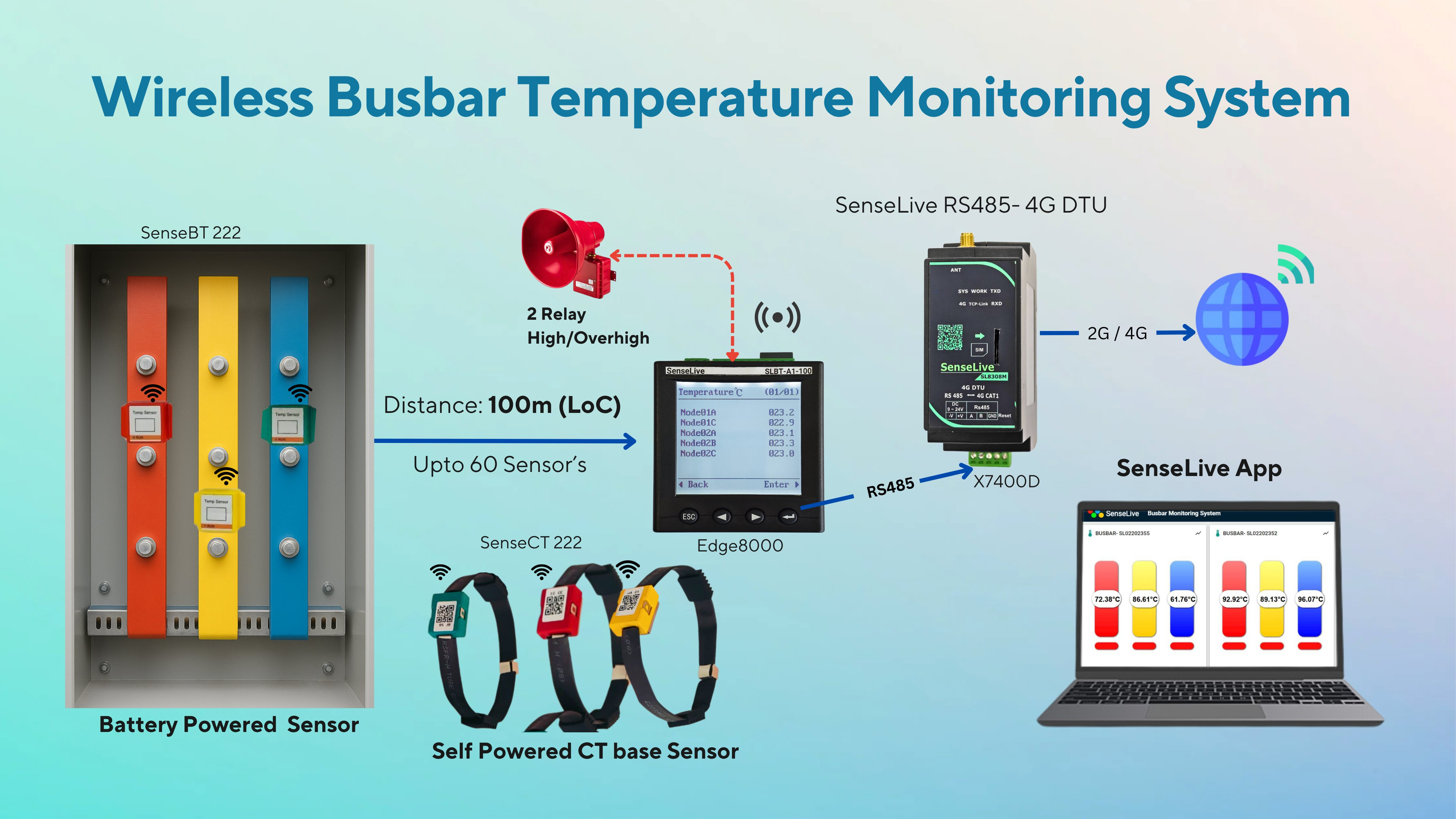

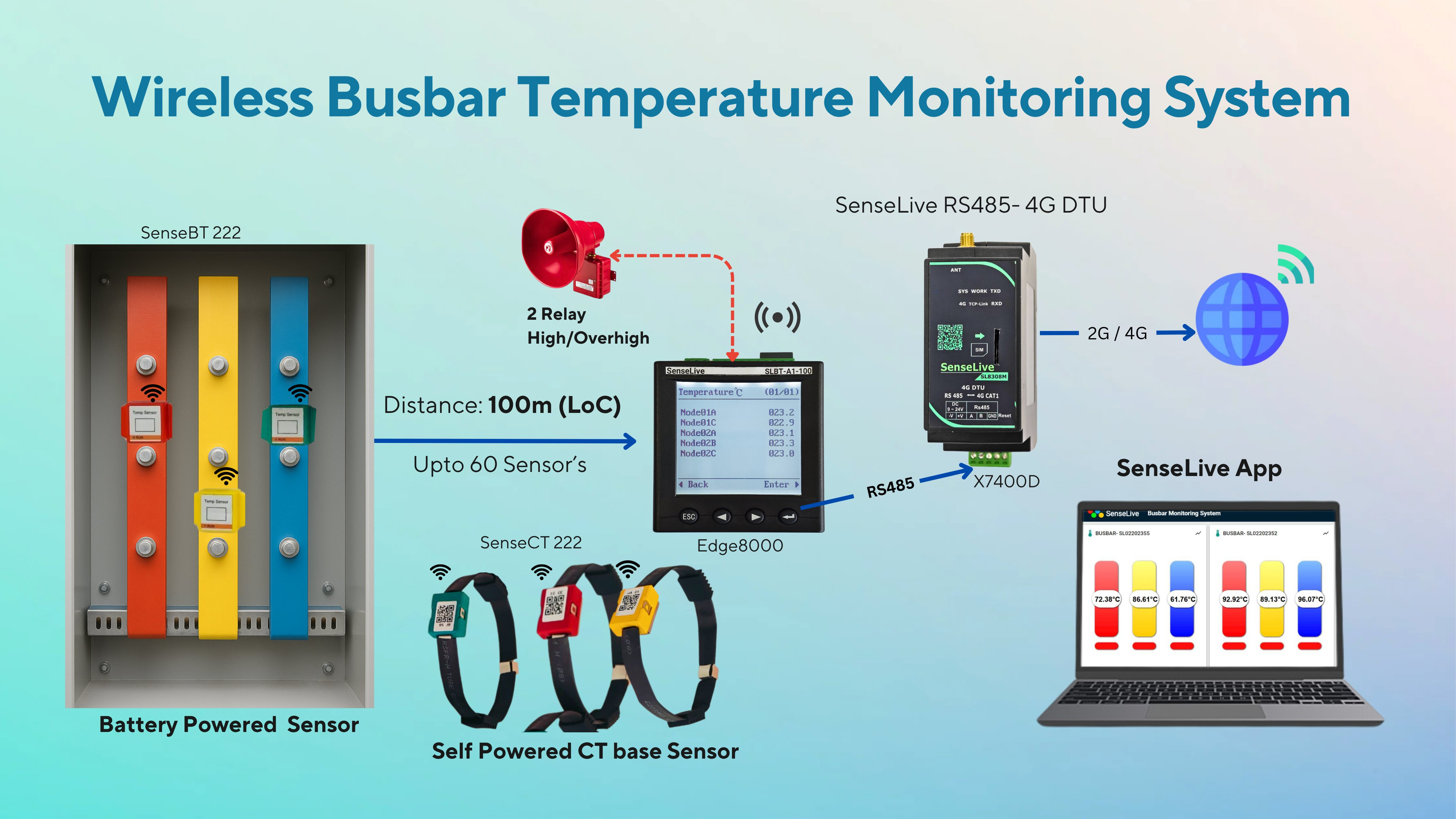

Wireless Busbar Temperature Monitoring System (WBTMS)

SenseLive’s Wireless Busbar Temperature Monitoring System (WBTMS) provides real-time monitoring to prevent overheating, enhance safety, and optimize electrical performance in data centers, industrial facilities, and renewable energy systems. With advanced wireless sensors and cloud-based analytics, WBTMS ensures reliability and efficiency.

Key Features

Edge-Based Thermal Intelligence

Monitor busbar temperature in real time using wireless sensors with local caching, scaling, and intelligent edge alerts.

Wireless Sensor Network

Supports up to 60 CT- or battery-powered sensors per controller with long-range 470 MHz communication.

SCADA & Cloud Integration

Seamlessly integrates with SCADA systems and cloud dashboards using Modbus-RTU and optional 4G connectivity.

Hotspot & Fault Detection

Instant overheating alerts and relay outputs help prevent arc-flash, insulation breakdown, and equipment failure.

Historical Logging & Analytics

Log real-time data for predictive maintenance and compliance with NB/T 42086, IEC 61439, and IEEE 1584.

Industrial-Grade Reliability

Works in harsh conditions (–50°C to +125°C sensors, –10°C to +55°C controller) with IP68-rated wireless nodes.

Overview

The SenseLive Wireless Busbar Temperature Monitoring System (WBTMS) is a cutting-edge Industrial IoT solution designed for continuous, real-time monitoring of busbar temperatures within electrical panels. Aimed at preventing electrical faults, enhancing safety, and optimizing energy efficiency, WBTMS enables proactive thermal management of critical infrastructure. The system consists of the Edge8000 controller, which acts as the central processing and display unit, along with SenseBT222 battery-powered wireless sensors and SenseCT222 CT-powered, maintenance-free sensors. It offers seamless integration with existing SCADA systems and cloud platforms, making it ideal for deployment across industrial, commercial, and utility-scale electrical installations.

Complete Feature Set

Real-Time Thermal Monitoring

Continuously tracks busbar temperatures to detect hot spots and prevent electrical faults.

SCADA & Cloud Integration

RS-485 Modbus-RTU and optional 4G DTU enable seamless SCADA and cloud-based remote monitoring.

Wireless Sensor Network

Supports up to 60 wireless sensors per controller using robust 470 MHz communication.

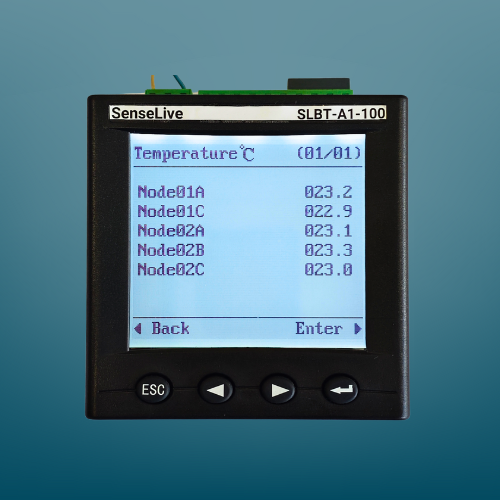

Local Display & Alerts

Real-time display with digital I/Os and relay-based alarms for immediate fault response.

Predictive Maintenance & Compliance

Enables historical data logging and trend analysis; compliant with NB/T, IEC, and IEEE standards.

Components Used

SenseLive Edge8000

Wireless Bus Bar Temperature Monitoring System

- Wireless temperature monitoring

- Integrated energy metering

- Dual relays for control

- Real-time alerts and notifications

SenseBT-222

Battery-Powered Wireless Temperature Sensor

- Long Battery Life

- Wide Range

- Industrial Design

- Wireless Communication

SenseCT-222

CT-Powered Wireless Temperature Sensor

- Self-Powered

- Real-time Monitoring

- Easy Installation

- Maintenance-Free

Dashboard Description

Gain actionable insights with the SenseLive WBTMS. Data from all wireless busbar sensors is accessible via local display on the Edge8000, and can be integrated into your existing SCADA systems or cloud platforms for remote monitoring, trend analysis, and comprehensive reporting.

This enables proactive management of your electrical assets.

Complete Feature Set

- Modbus-RTU for SCADA and BMS integration

- Real-time temperature display on Edge8000

- Optional 4G DTU for cloud connectivity and mobile access

- Historical data logging for trend analysis and predictive maintenance

Key Applications

Busbar Overheat Detection

Monitor thermal conditions of busbars in LV/MV switchgear to prevent arc-flash, insulation damage, and electrical faults.

UPS & Energy Storage Monitoring

Track thermal patterns in UPS and battery systems to prevent overheating and extend operational life.

PDU Monitoring in Data Centers

Ensure reliable power distribution by continuously sensing temperature in PDU enclosures and terminals.

Control Panel Thermal Management

Protect transformers, breakers, and relays from heat-related failures in industrial automation panels.

HVAC and Chiller Line Monitoring

Optimize energy use and spot inefficiencies by tracking temperatures in ducts and chilled-water pipes.

Cold Storage Compliance

Ensure food/pharma compliance with real-time monitoring and historical temperature audit trails.